1. What is OEM service?

Clients should send us their original design artworks or original samples they want to copy. We produce new molds

accordingly to develop the new products. All mold costs are paid by the customers and the products are produced

only for them. We keep all molds and product info secret and don’t produce the same products for any other customers.

Disadvantage: high cost, long lead time, high MOQ

Advantage: unique design, exclusive right to molds

2. What is ODM service?

Clients only need to choose from our existing designs, and provide decoration design. Usually, they don’t change molds.

Disadvantage: public molds, open to other brands

Advantage: low cost, short lead time, low MOQ

3. What service can I get before placing an order?

To help client find the ideal packaging, we provide professional advice according to clients’ need, free samples,

and sample customization. Clients could get pre-production samples 95% similar to production samples.

4. What service do you provide after I place the order?

Our mass production will strictly follow the standard of approval samples by clients. Clients will be kept informed

about production progress. Shipping and delivery will be arranged under DAP, DDU and DDP terms.

5. What is your after sale service?

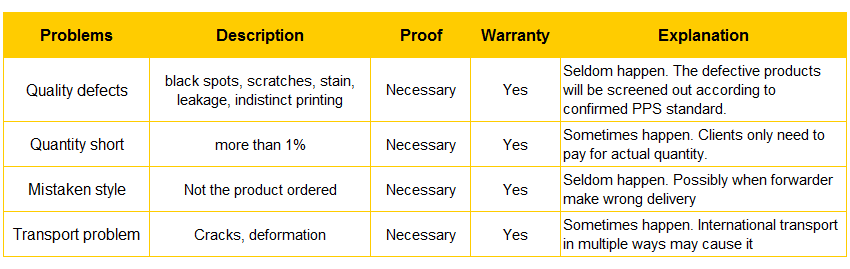

Welcome client’s feedback and comments on our products anytime. Any complaint should be treated seriously

and problems should be solved properly. Our 1-year warranty policy covers most problems clients may meet as below.

We will compensate for above problems within one year after clients receive the goods. Clients could be rest assured.

6. How do you make compensation?

Thanks to control policy of foreign currency in China, it is difficult and complicated to transfer dollars or pounds back to

clients account. If quantity of compensation is small, less than MOQ, we can hardly put it on mass production line. Also

transport for small quantity is also a problem. International express may result in damages.

That is why we usually compensate in two ways,

A.deduct compensation from advance of next order when client order a different product

B.add compensation quantity to next order for free when client reorder the same product

7. Do you keep client info and designs secret?

Yes, we are responsible to protect client info and order info. That is why there is no client info on our website.

We only provide samples without client's logo to new clients.

Sunny Jiang

Sunny Jiang